Production

Production was undertaken by Sandock which produced the vehicle hulls at its shipyard in Durban before having them transported by rail to Boksburg.

Background

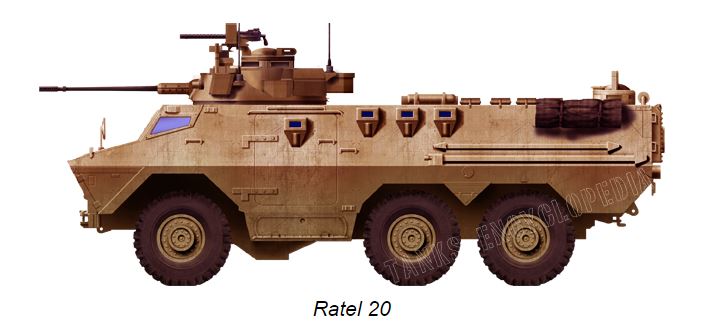

Design work on the 6×6 wheeled Ratel was intended to carry troops rapidly into and out of battle, making mobility the primary characteristic, followed by firepower and armour.

Approximately 1400 Ratels were built and have been exported to Cameroon, Djibouti, Ghana, Jordan, Libya, Morocco, Rwanda, Sahrawi Arab Democratic Republic, Senegal, Yemen and Zambia.

The Ratel`s 6×6 wheeled configuration was designed for the African battle space and characterized by its versatility and cross-country capability.

A six-wheel run flat (designed to resist the effects of deflation when punctured) configuration offered more reliability and required less maintenance than tracked vehicle.

History

The South African Army needed new armoured vehicles for more conventional warfare operations, to replace the Saracens and Elands, and to be able to provide more effective support for the tank force. This programme started in the early 1970s, when the South African Army decided to go with a new concept the armoured infantry fighting vehicle (AIFV, but usually referred to in South Africa as IFV).

An AIFV carries a powerful gun (20 mm or 30 mm) as well as a squad of troops, who have their own vision ports and firing ports, so that they can fight from within the vehicle.

So, around 1975/1976, the South African Army decided to adopt an AIFV based on the Springfield Bussing vehicle.

This became the Ratel (honey badger, in English), which was mass-produced by Sandock Austral.

The monocoque design, the Ratel hulls were made in Sandock Austral's Durban dockyard and taken by rail to Boksburg for fitting out.

The turrets were based on those on the Eland armoured cars - the 20-mm gun turret of the standard Ratel IFV, for example, was a redesigned Eland 90 turret.